Mission Compound, Jhansi, Uttar Pradesh

Ladle Slide Gate System Spare Parts

The ladle slide gate system is an essential component of a continuous casting machine (CCM) used in the steel industry. It plays a crucial role in controlling the flow of molten steel from the ladle to the tundish, which then feeds the casting mold.

As a supplier of Continuous Casting Machine (CCM) ladle slide gate systems and its spare parts, Our company plays a crucial role in supporting the steel industry's continuous casting process. The ladle slide gate system is a vital component of the CCM, ensuring the controlled flow of molten steel from the ladle to the tundish and eventually into the casting mold. It enables operators to regulate the casting speed, adjust the steel temperature, and prevent the entry of slag or other impurities into the mold. This system contributes to the production of high-quality steel products with consistent dimensions and properties.

We provide the necessary ladle slide gate components, including slide gate mechanisms, refractory slide plates, collector nozzles, and any other related parts. Our expertise lies in delivering high-quality, reliable systems that meet the specific requirements of your customers.

To maintain a competitive edge, we focus on several aspects:

Quality Assurance: Ensuring the highest standards of quality in your ladle slide gate systems is crucial.

Customization: We work closely with our customers to understand their specific requirements and provide customized solutions accordingly. Adaptability and flexibility in our product offerings helps us meet diverse customer needs.

Innovation and Technology: We keep abreast of the latest advancements in ladle slide gate technology.

Customer Support: We provide excellent customer support services, including technical assistance, troubleshooting, and after-sales support. Building strong relationships with our customers helps us establish a reputation for reliability and responsiveness.

Collaboration: We foster partnerships and collaborations with other industry stakeholders, such as steel producers, CCM manufacturers, and research institutions.

We have built a strong reputation for supplying high-quality silicon O-rings and providing excellent customer support that has helped our company thrive in the ladle slide gate system market.

Laddle Slide gate System Spare Parts Table

| S.No. | Parts Name |

| 1 | Adaptor Frame |

| 2 | Housing |

| 3 | Fixed Plate Holder |

| 4 | Slider |

| 5 | Nozzle Holder |

| 6 | Housing Cover |

| 7 | Cylinder Bracket |

| 8 | Extension Rod |

| 9 | Eccentric Clamping Device |

| 10 | Expansion Compensating Nut |

| 11 | Eye bolts |

| 12 | Gliders |

| 13 | Gliding Rails |

| 14 | Guide Bush |

| 15 | Key for adaptor frame |

| 16 | Hinge Pin |

| 17 | Centering Ring |

| 18 | Fixed Plate |

| 19 | Sliding Plate |

| 20 | Exchange Collector Nozzle |

| Business Type | Exporter, Supplier |

| Material | Metal |

| Shape | Round |

| Color | Black, Grey |

| Condition | New |

| Pressure | High Pressure, Low Pressure, Medium Pressure |

| Applications | Steelmaking, Foundries, Other metalworking industries |

It is a critical component in ladle slide gate systems. It is used to provide a cushion of air between the ladle and the slide gate, which helps to prevent leaks and ensure smooth operation.

Features :

- Made from high-quality materials

- Durable construction

- Easy to install and maintain

- Helps to prevent leaks

- Ensures smooth operation

Benefits :

- Increased safety

- Reduced maintenance costs

- Improved efficiency

- Extended lifespan of the ladle slide gate system

| Business Type | Exporter, Supplier |

| Color | Silver |

| Finishing | Polished |

| Material | Steel |

| Shape | Round |

| Condition | New |

| Usage | Industrial |

| Corrosion Resistance | Yes |

| Specialities | Precise Design, Fine Finish, Precisely Designed |

A centring ring is a component of a ladle slide gate system that helps to align the slide gate with the ladle. This is important to prevent leaks and ensure the smooth flow of molten steel.

There are many different types of centring rings available, so it's important to choose the right one for your application. Some factors to consider include the size and shape of the ladle, the type of slide gate, and the refractory material.

We provide you with a centring ring that meets your specific needs and offer advice on the best type of centring ring for your application.

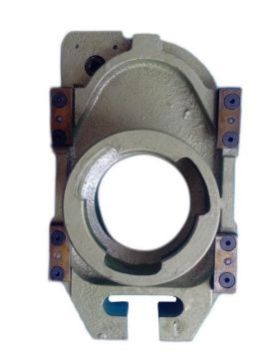

| Business Type | Exporter, Supplier |

| Material | Metal |

| Application | Automotive Industry, Industrial |

| Color | Red |

| Feature | High Durability, Impeccable Finish, Rugged Design, Simple Installation |

| Condition | New |

| Finishing | Polished |

| Packaging Type | Box |

The housing cover in a ladle slide gate system is a protective cover that encloses the slide gate mechanism. It is typically made of steel and is designed to protect the mechanism from the elements and from accidental damage. The housing cover also helps to keep the molten steel contained within the ladle.

The housing cover is an important safety feature in a ladle slide gate system. It helps to protect the operator from molten steel and from the moving parts of the mechanism. It also helps to prevent accidental spills of molten steel.

Here are some of the benefits of using a housing cover in a ladle slide gate system :

- Protection from the elements

- Protection from accidental damage

- Containment of molten steel

Overall, the housing cover is an important safety feature in a ladle slide gate system. It helps to protect the operator, the mechanism, and the molten steel from damage.

| Business Type | Exporter, Supplier |

| Type | Metal Plates |

| Material | Metal |

| Thickness | 10-15mm |

| Color | Grey |

| Feature | Attractive Design, Fine Finish, High Quality, High Strength, Stain Proof, Stylish |

| Finishing | Polished |

| Country of Origin | India |

| Usage | Industrial |

The inner plate in a ladle slide gate system is located at the bottom of the ladle. It is the first plate that the molten steel flows over when it is being transferred from the ladle to the tundish. The inner plate is typically made of a high-temperature resistance material that is resistant to corrosion and erosion.

Here are some of the benefits of using an inner plate in a ladle slide gate system :

- Control of molten steel flow : The inner plate can be adjusted to control the amount of molten steel that flows through the gate. This helps to ensure that the molten steel is transferred to the tundish at a consistent rate.

- Protection of ladle : The inner plate helps to protect the ladle from damage from the heat and chemicals in the molten steel. This helps to extend the life of the ladle and prevents costly repairs.

- Prevention of splashing : The inner plate helps to prevent the molten steel from splashing out of the ladle. This helps to prevent injuries to operators and damage to the surrounding area.

| Business Type | Exporter, Supplier |

| Material | Forged Steel |

| Color | Silver |

| Feature | Blow-Out-Proof, Casting Approved, Corrosion Proof, Durable, Good Quality |

| Condition | New |

| Pressure | High, Low, Medium |

| Country of Origin | India |

| Application | Industrial |

As a supplier of complete slide gate systems, We provide a range of products and services related to slide gates. In a furnace application, a slide gate system can be used to control the flow of materials within the furnace, such as the movement of molten metal, slag, or other materials.

In steelmaking, a ladle slide gate system is used to control the flow of molten steel from the ladle to the tundish or casting mold. The slide gate mechanism is integrated into the ladle's bottom and is operated to open or close the passage, allowing or blocking the flow of steel.

The slide gate system consists of several key components. These include :

- The Slider

- Nozzle

- Housing

- Support Structure

- Actuation Mechanism.

| Business Type | Exporter, Supplier |

| Material | Metal |

| Application | Industrial |

| Color | Grey |

| Condition | New |

| Finishing | Polished |

| Country of Origin | India |

| Density | 5.45 G/cm3 |

In a ladle slide gate system, the slider is a key component that plays a crucial role in controlling the flow of molten steel. The slider is an integral part of the slide gate mechanism and is responsible for opening or closing the passage through which the molten steel flows.

Here's a closer look at the slider in a ladle slide gate system:

- Purpose : The slider is designed to create a tight seal when closed, preventing molten steel from leaking out of the ladle. When the slider is opened, it allows the controlled flow of molten steel into the tundish or casting mold.

- Design : The design of the slider depends on various factors such as the size of the ladle, flow rates, and desired control precision. It is usually a rectangular or trapezoidal-shaped plate that fits within the housing of the ladle slide gate system.

| Business Type | Exporter, Supplier |

| Material | Metal |

| Application | Nozzle Holding |

| Color | Grey |

| Feature | Heat Resistance, Highly Durable, Non Breakable, Rustproof, Sturdy Design |

| Condition | New |

| Finishing | Polished |

| Country of Origin | India |

| Surface Treatment | Anodized |

In a ladle slide gate system, the nozzle holder is a critical component that supports and positions the nozzle, which controls the flow of molten steel. The nozzle holder plays an important role in ensuring accurate and controlled pouring of steel from the ladle to the tundish or casting mold.

It plays an integral part in achieving accurate and controlled pouring of molten steel during the steelmaking process. Its proper design, construction, and alignment with the nozzle and slide gate are essential for maintaining productivity, efficiency, and quality in steel casting operations.

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Material | Stainless Steel |

| Finishing | Polished |

| Corrosion Proof | Yes |

| Speciality | Perfect Shape, High Strength, Fine Finished, Excellent Quality, Crack Proof |

| Coupling Length | 16mm, 22mm, 26mm |

A quick release purging coupling is a type of coupling that is used in ladle slide gate systems to allow for quick and easy purging of the system. The coupling typically consists of two halves, which are connected by a quick release mechanism. When the mechanism is released, the two halves of the coupling can be separated, allowing for the purging of the system.

The quick release purging coupling is a valuable safety feature in ladle slide gate systems. It allows for the quick and easy purging of the system in the event of a spill or leak. This helps to prevent the spread of contamination and to protect the operators from exposure to hazardous materials.

Our Quick Release Purging Coupling is designed to provide efficient and reliable purging capabilities for ladle slide gate systems in the steel industry. With its innovative features and high-quality construction, it is an essential component for maintaining the optimal performance of ladle slide gate systems.

| Business Type | Exporter, Supplier |

| Material | Silicone Rubber |

| Shape | Round |

| Thickness | 10-20mm |

| Application | Connecting Joints, Pipes, Tubes |

| Color | Red |

| Feature | Fine Finish, Good Quality, Heat Resistant, Robust Construction, Unbreakable |

| Country of Origin | India |

Silicon O-rings are an important component of ladle slide gate systems. They are used to seal the interface between the slide gate and the ladle, preventing molten steel from leaking out.

They are made of a high-temperature resistant silicone rubber that can withstand the high temperatures of molten steel. They are also resistant to chemicals and other fluids.

We supply Silicon O-rings in a variety of sizes and shapes to match the specific ladle and slide gate. They are also available in a variety of durometers, which is a measure of the hardness of the rubber.

| Business Type | Exporter, Supplier |

| Material | Metal |

| Application | Cylindrical Sealing |

| Color | Blue |

| Feature | Accurate Dimension, Easy To Install, Fine Finish, Good Quality, Heat Resistant, Robust Construction, Unbreakable |

| Condition | New |

| Country of Origin | India |

A slide gate cylinder is a hydraulic cylinder that is used to open and close a slide gate. The cylinder is typically made of steel and has a piston that is connected to the slide gate. The coupling is used to connect the cylinder to the slide gate, and the seal is used to prevent leaks.

The slide gate cylinder is an important part of a ladle slide gate system. It is responsible for opening and closing the slide gate, which allows the molten steel to flow into or out of the ladle. The coupling and seal ensure that the cylinder operates properly and that there are no leaks.

We provide slide gate cylinders with coupling and seal in a variety of sizes and pressure ratings. The size of the cylinder is determined by the size of the slide gate, and the pressure rating is determined by the pressure of the molten steel.

| Business Type | Exporter, Supplier |

| Type | Eye Bolts |

| Material | Metal |

| Application | Automobiles, Automotive Industry, Fittings |

| Color | Black |

| Feature | Accuracy Durable, Auto Reverse, Corrosion Resistance, Dimensional, Hardend & Temper, High Quality, High Tensile |

| Technics | Black Oxide |

| Surface Finishing | Polished |

| Country of Origin | India |

| Bolt Shape | Eye Shape |

The eye bolt is an essential part of the ladle slide gate system and is used for various purposes related to installation, maintenance, and operation. The eye bolt is a threaded bolt with a loop or eye-shaped attachment at one end. It is designed to provide a secure attachment point or connection for various components and accessories within the ladle slide gate system.

We ensure that the eye bolts we provide meet the necessary quality standards, specifications, and compatibility requirements of the ladle slide gate systems. Additionally, we would offer support and guidance to customers regarding proper installation, maintenance, and safety practices related to the eye bolts in the ladle slide gate system.

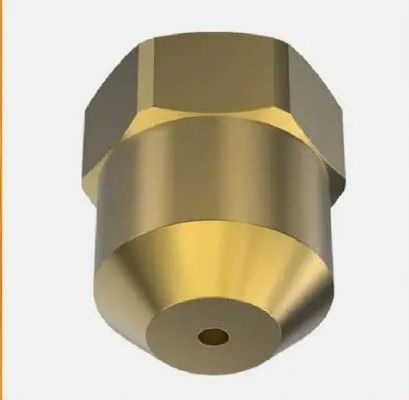

| Business Type | Exporter, Supplier |

| Material | Steel |

| Application | Industrial Use |

| Color | Golden |

| Condition | New |

| Finishing | Polished |

| Pressure | High, Low, Medium |

| Country of Origin | India |

Spray nozzles are an important component of ladle slide gate systems. They are used to spray water or other fluids onto the molten steel to cool it and prevent it from splashing.

Here are some of the benefits of using spray nozzles in ladle slide gate systems :

- Cooling of molten steel : Spray nozzles help to cool the molten steel by spraying water or other fluids onto it. This prevents the molten steel from splashing and helps to maintain its temperature.

- Prevention of splashing : Spray nozzles help to prevent the molten steel from splashing by spraying water or other fluids onto it. This helps to protect the operators and equipment from molten steel.

- Improved quality of steel : Spray nozzles help to improve the quality of the steel by cooling it evenly. This helps to prevent defects in the steel and ensures that it meets the required specifications.

We provide spray nozzles made of high-quality material and are available in a variety of sizes and shapes to meet your specific needs.

| Business Type | Exporter, Supplier |

| Material | Metal |

| Thickness | 2.5-3mm |

| Color | Silver |

| Surface Finishing | Polished |

| Application | Steelmaking, Foundries, Other metalworking industries |

| Benefits | Ensures accurate torque settings, Easy to use, Durable construction, Long lifespan |

Torque wrench with socket is the perfect tool for tightening and loosening ladle slide gate valves. The wrench features a precision-machined socket that fits snugly on the valve stem, ensuring accurate torque readings. The wrench also has a comfortable grip and a built-in ratchet mechanism for easy operation.

Features :

- Precision-machined socket for accurate torque readings

- Comfortable grip

- Built-in ratchet mechanism

- Made from high-quality materials

- Comes with carrying case

| Business Type | Exporter, Supplier |

| Material | Metal and Rubber |

| Shape | Round |

| Color | Black, Grey |

| Condition | New |

| Pressure | High Pressure, Low Pressure, Medium Pressure |

| Country of Origin | India |

It is a critical component in ladle slide gate systems. It is used to provide a cushion of water between the ladle and the slide gate, which helps to prevent leaks and ensure smooth operation.

Features :

- Made from high-quality materials

- Durable construction

- Easy to install and maintain

- Helps to prevent leaks

- Ensures smooth operation

Benefits :

- Increased safety

- Reduced maintenance costs

- Improved efficiency

- Extended lifespan of the ladle slide gate system